Grip conveyor belt

What is a conveyor belt grip?

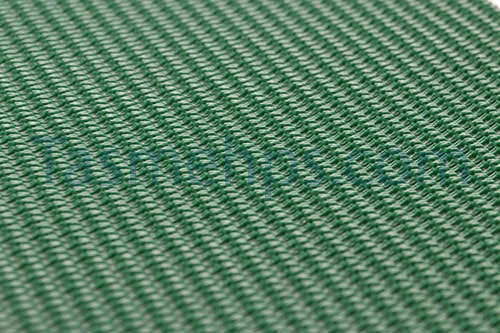

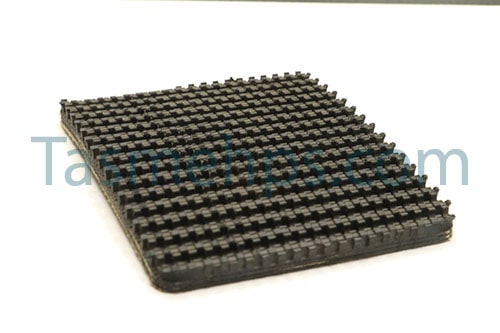

Grip conveyor belt is one type of industrial belt that is produced in different sizes with its own shape. Grab conveyor belt has a grooved and layered appearance similar to the shapes of honeycombs, and for this reason it is also known as honeycomb belt . Usually, these belts are used with a thickness of 5-4 mm and a thickness of 7-8 mm more than other existing grips. Their material is usually made of fabric, PVC or layered manjid. Due to the special surface on it, this conveyor has the ability to catch and transfer objects.

This special surface, which is called “grip” or “grip pattern”, is usually produced using special materials such as rubber or polyamide. Due to the special grip surface, it can easily take loads and different materials and transfer them from one point to another. Its main function is based on the friction between the surface of the grip and the objects, which makes for a safe and reliable transfer. Grip conveyors are used in various industries, including production lines, food industry, packaging industry, semi-solid and liquid material transfer, mining industry, steel industry, automotive industry, etc. This conveyor belt can improve the performance of industries and help increase the productivity and safety of employees due to the ability to take loads and materials with accuracy and easy manipulation.

Grip conveyor belt structure and components

Grip conveyor belt material

Grip conveyor belts are usually made of orthoplastic (such as neoprene rubber) or polyamide (such as nylon) materials. These materials are used to create a suitable grip surface and durability against pressure and friction.

Grip pattern

The grip pattern is usually created by using raised patterns, lines or other designs on the surface of the belt. The grip pattern gives the conveyor the ability to stick and grab loads and materials.

Covering layers

They have coating layers that can strengthen the physical and chemical properties of the belt. These layers can increase the resistance to pressure, heat, oil, acids and bases and increase the useful life of the belt.

Resistive layer

Some grip conveyor belts have a resistance layer that is used to resist wear and other mechanical damage. This layer is usually placed on top of the belt and can be resistant to possible damage. Grip conveyor is one of the most used types of conveyor belts.

Important systems in the Grip ribbed conveyor belt

- Connection system: Grip needs a connection system so that it can be properly installed in devices and machines. The fastening system can include locks, screws, adhesives, grooves or welding. These systems must be strong and durable to hold the belt securely in place.

- Rails and rollers: The grip conveyor is placed on rails and moves with the help of rollers. Rails are usually made of metals such as steel, and rollers are placed on them. Rollers are made of durable material and with their help, the conveyor belt is correctly placed on the track and it is prevented from slipping.

- Motor and motion system: To move the grip conveyor belt in order to transfer loads and materials, a motor and motion system are needed. The motor is usually located on one side of the conveyor belt and rotates the belt by connecting to a suitable motion system.

The price of grip conveyors

Grip conveyor price depends on several factors, the most important of which are:

Belt dimensions

The size and dimensions of the belt directly affect its price. Larger and wider belts cost more.

Manufacturer

Different companies produce industrial belts with different qualities and prices. Therefore, the prices are also different.

The material of the grip belt

Grip tape can be made of different types and materials. The material and quality of the belt has a great impact on its price. Belts made from high-quality materials may be more expensive.

Grip belt type and model

According to different industrial needs, Grip conveyor belts are supplied with various models and features. The model and special features of the belt may be added to its price.

Advantages and features of the Grip conveyor

- Transporting loads and materials: Grip conveyor belt is able to transport various loads and materials safely and reliably from one point to another. The grip pattern on the surface of the belt prevents loads and materials from slipping and allows the transfer to take place quickly and without problems.

- Resistance to pressure and heat: Grip is usually made of materials that have high resistance to pressure and heat. These features can enable the belt to withstand heavy loads and various environmental conditions.

- Application in different environmental conditions: It can work in different environmental conditions including temperature, humidity, acids and bases. These features make the conveyor belt usable in various industries such as food industry, chemical industry and mining industry.

- Transmission in curved and curved areas: Thanks to the flexibility and grip properties of the belt, it can work in curved and curved areas. This means the possibility of transferring materials in tighter bends and curves, which is important in some industries.

- Precedence of pressure adjustment: Maybe in order to perform optimally, in some cases it is necessary to adjust the pressure of the grip surface of the grip conveyor. By adjusting the pressure, you can adjust the amount of adhesion and grip of the material on the surface of the belt. This ability can take and transfer materials with proper accuracy and sensitivity in a controlled manner.

- Carrying small and irregular loads: Grip has the ability to carry small and irregular loads due to its grip pattern and special surface. Materials such as solid particles, small parts, powder materials, or packaged materials with irregular shapes can be transported using a grip conveyor.

- Fast and accurate operation: Grip conveyor belt is able to operate quickly and accurately due to its grip and non-slip properties. This advantage can be used in production lines with the need for fast movements and precise coordination between different components.

- Saving time and manpower: Using a conveyor can save time and manpower. Instead of manually transporting loads and materials, Grip does it automatically and enables the transfer of heavy and bulky loads. The conveyor belt is used as an effective solution in various industries by combining these features.

Uses of grip conveyor belt

In food production and packaging factories, due to health issues and health rules, the use of plastic grip belts is not common; But the use of PVC grip belt is common in factories and industries of food production and packaging due to the presence of antibacterial material in this belt. However, the use of grip conveyor belts is used in many industries, including the following industries.

- Mining Industry: In the mining industry, grab conveyors are used to transport minerals such as coal, iron ore, copper, iron ore, oil, gypsum and iron ore.

- Cement industry: Grip belts are used in the cement industry to transport raw materials such as lime, clay and silica. Also, it is used in the transfer of clinker, cement powder and ready materials.

- Automotive industry: In the automotive industry, grip conveyor belts are used to transport car parts such as chassis, body, interior parts and accessories.

- Packaging industry: used to transport packages, cartons, bottles, boxes and other packaging materials.

- Steel Industry: Grip belts are used to convey materials such as crushed iron ore, molten iron, plates and heavy parts.

- Buy conveyor belt

- Buy a power transmission belt

- Buy a timing belt

- Buying a treadmill belt

- Buy PVC belt

- Buy PU belt

- Buy grooved belt

- Buy Grip conveyor belts

- Buy polycard belt

- Buying elevator belts

- Purchase of food conveyor belts

- Purchase of carton belt

- Purchase of printing and packaging belts

- Buy steel mesh conveyor belt

- Buy fasteners

- Belt apparatus

Sale of all types of grip conveyor belts

Archit Company has always tried to offer the best quality of conveyor belts in the sale of power transmission belts and conveyor belts. It is possible to buy Grip conveyor from the leading store of the industry by phone, online and also in person and visiting the store.

To buy all kinds of belts from all over the country, you can contact the numbers listed on the website. According to the devices available in your industry, the belt desired by the customer is cut from the rolls to the appropriate size and quality and professionally made. If you need guidance on buying a belt, you can use the free consultation of the industry leader.